What is a PTC Finned Resistor Heater?

PTC Finned Resistor Heaters or Air Flow Heaters are specially designed to heat a large volume of air. The fins or honeycomb structure of the heater offers a large surface and allows for efficient heat transfer into the air stream.

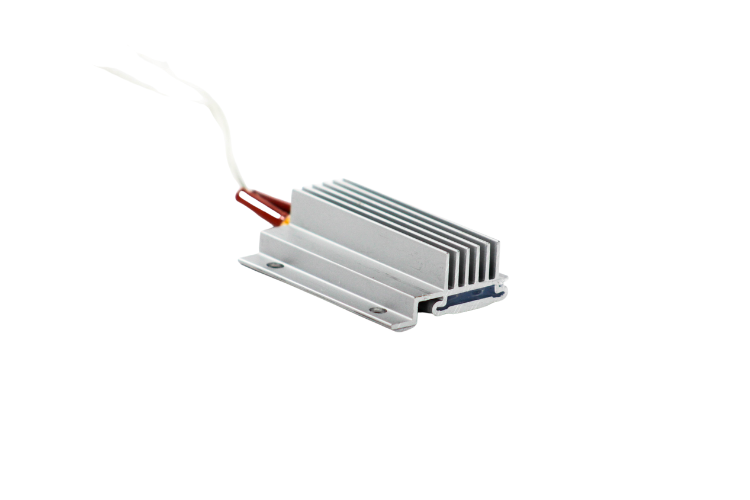

DBK Standard HRKK Air Heaters have V-shaped fins, and our newer HRP models are fully insulated and offer an option for delta-shaped fins to provide high heat output with minimal pressure loss.

The HR Family of heaters use PTC Heating Elements which have a temperature limiting effect; this provides an additional safety feature with little chance of combustion to surrounding surfaces.

What is the advantage of PTC Air Heaters over other heaters?

Apart from the heating function, PTC Finned Resistor Heating Elements perform with an independent temperature limiting effect. This results in a highest possible operating safety. The big surface of the aluminium fins ensures a homogeneous heat transfer with low outlet. By an adjustment of the air volume flow, this system allows an automatic regulation of the heating power in certain ranges.

What is the difference between the three types of PTC Air Heaters: HRKK-V, HRKK Delta and HRP?

From a technical point of view, the three types differ mainly in their fin shape and electrical insulation. PTC Air Heaters of the HRKK-V series come with traditional v-shaped fins and live parts. PTC Air Heaters of the HRKK-Delta series are equipped with patented delta-shaped fins but also have live parts. Insulated PTC Air Heaters of the HRP series can be ordered with either v- or delta-shaped fins and are electrically insulated.

HRKK-V: V-shaped fins / live parts

HRKK Delta: Delta-shaped fins / live parts

HRP: V- or Delta-shaped fins / electrically insulated

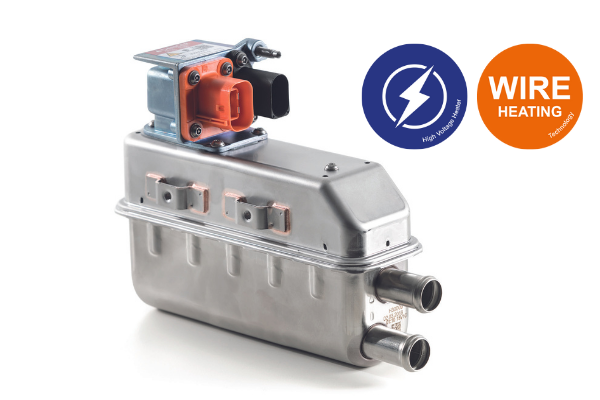

What are special features of the HRP series?

The HRP range are the only type of air heaters to feature electrically insulated heating elements. As a result, the air heaters are more resistant to moisture and dirt. Due to their characteristics, HRP's should only be controlled using PWM (pulse width modulation) to avoid thermo-mechanical stress within the heating element.

There are two types available:

Note: Please always specify your specific application purpose when submitting your inquiry. These products are based on a modular system and are suitable for many fields of application. The specific area of application should always be discussed with our sales department in advance - we will be happy to advise you individually!

What is the surface temperature of a PTC Air Heater? What is the maximum air outlet temperature?

The surface temperature of PTC Air Heaters depends on the PTC, the air inlet temperature and the air flow rate. In case of failure, the surface can only become as hot as the pre-defined PTC temperature. The maximum temperature of the PTC can be selected between 176°F and 464°F. Note: Reducing the temperature also reduces the performance.

Is it possible to operate PTC Air Heaters without an additional temperature fuse?

PTC Air Heaters are fail-safe thanks to the PTC effect. Even in the event of a failure (no air flow) they cannot overheat. However, in order to protect surrounding components that are not temperature-resistant, we recommend to use a thermal switch that switches off the heater in the event of failure.

How can I control the power output of PTC Air Heaters?

The power output of PTC Air Heaters can be adjusted by altering the air flow rate. The following applies: little air, little power - lots of air, lots of power. In addition, we recommend the following options for power control:

HRKK series: switching or timing of individual heating circuits is possible; more precise control via PWM.

HRP series: regulation exclusively via PWM, switching or clocking of individual heating circuits is NOT possible.

Can I use a PWM power control for PTC Air Heaters? Under which conditions?

In general, power regulation using pulse width modulation (PWM) is possible. However, there are some specific details to be considered. Please contact us for support.

Can I operate PTC Air Heaters at a wide voltage range and what are the consequences?

Yes. A great advantage of PTC heating technology is its multi-voltage capability. Low voltage variants are possible as well. Please note that due to Ohm's law, the inrush current increases with higher voltage. The output remains almost the same. Please refer to the respective data sheet of the individual product and contact us for technical support in case of doubt.

Which factors must be considered when connecting a PTC Air Heater?

Due to their self-limiting characteristic, PTC Air Heaters must always be switched in parallel, otherwise they will limit each other. Futher, we recommend to use a time-delay fuse due to the increased inrush current.

What are typical applications of PTC Air Heaters?

PTC Air Heaters are very flexible and can be used in any application that requires homogeneous heating of air flows. Those are, e.g.: Industrial machinery operator compartments, Railway applications, Cabin heating for special-purpose vehicles, Cockpit heaters, Control Cabinets, Air dryer & Dehumidifier, Pre-heaters or post-heaters for air conditioning and ventilation systems with heat recovery (Low energy residential housing), and much more.

PTC Air Heaters are based on a modular system and are suitable for many fields of application. The specific area of application should always be discussed with our sales department in advance - we will be happy to advise you individually!